PRODUCTS

홈

PRODUCTS

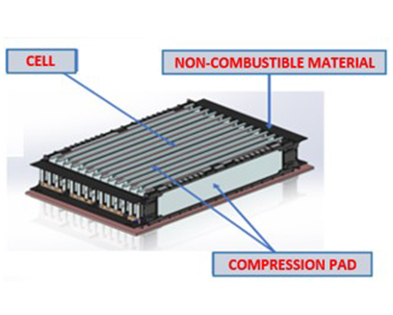

COMPRESSION PAD

Compression Pad

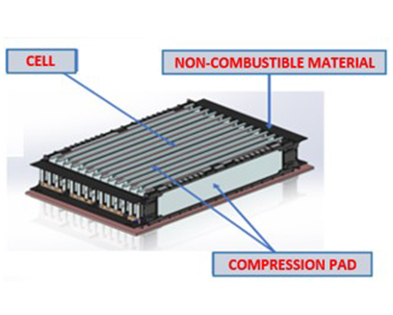

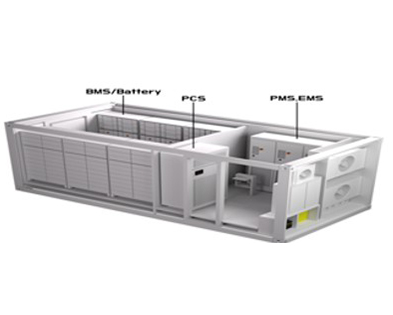

Key material for thermal runaway prevention in EV/ESS, with excellent compressibility, shock absorption, and non-combustibility.01Applications

ESS

Module

Rack

ESS Enclosure

EV

Module

Pack

EV

02Tailored to Customer Needs

03Product Description

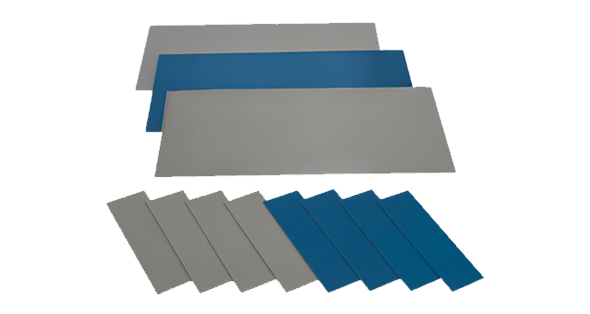

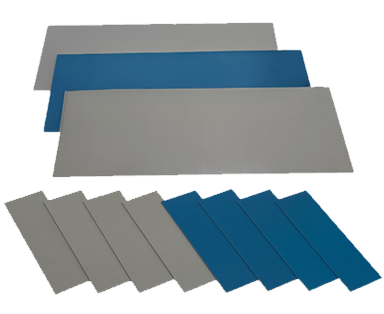

01CS Series

| Properties | Unit | Condition | Test Result | TEST Method |

|---|---|---|---|---|

| Color | Visual | - | GRAY | - |

| Density | g/cm3 | - | 0.2 ~ 0.4 | ASTM D792 KS M 6672 |

| Thickness | mm | - | 2 ~ 10 | ASTM D3767 |

| Flammability | UL94 | - | V0 FILM : VTM0 |

UL94 V |

| Thermal Conductivity | W/mK | - | < 0.08 | ASMT C518 |

| Compression Load | kpa | @20% | 5 ~ 20 | ASTM D3574 |

| @40% | 0 ~ 30 | - | ||

| Insulation resistance | Ω | 500VDC / 60sec | >10¹¹ | ASTM D257 |

| Withstand voltage | mA | 4.25kVDC / 60sec | < 0.01 | ASTM D149 |

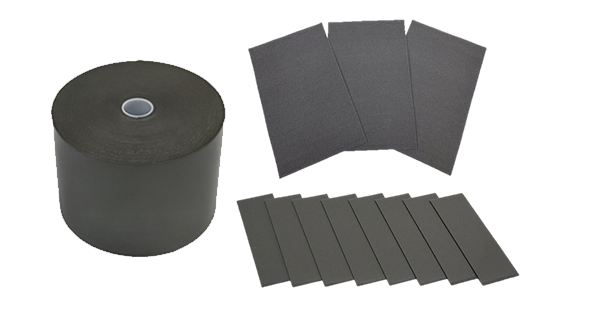

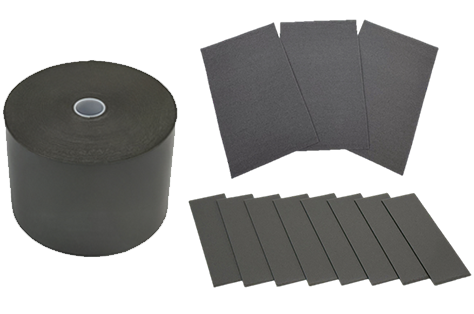

02CU Series

| Properties | Unit | Condition | Test Result | TEST Method |

|---|---|---|---|---|

| Color | Visual | - | Black | - |

| Density | g/cm3 | - | 0.15 ~ 0.3 | ASTM D792 KS M 6672 |

| Thickness | mm | - | 2 ~ 15 | ASTM D3767 |

| Flammability | UL94 | - | V0 FILM : VTM0 |

UL94 V |

| Thermal Conductivity | W/mK | - | < 0.05 | ASMT C518 |

| Compression Load | kpa | @20% | > 15 | ASTM D3574 |

| @40% | > 20 | - | ||

| Insulation resistance | Ω | 500VDC / 60sec | >10¹¹ | ASTM D257 |

| Withstand voltage | mA | 4.25kVDC / 60sec | < 0.01 | ASTM D149 |

03CSH Series

| Properties | Unit | Condition | Test Result | TEST Method |

|---|---|---|---|---|

| Color | Visual | - | Dark Gray | - |

| Density | g/cm3 | - | 0.4 ~ 1.0 | ASTM D792 KS M 6672 |

| Thickness | mm | - | 1 ~ 10 | ASTM D3767 |

| Flammability | UL94 | - | V0 | UL94 V |

| Thermal Conductivity | W/mK | - | < 0.06 | ASMT C518 |

| Compression Load | kpa | @20% | > 40 | ASTM D3574 |

| @40% | > 150 | - | ||

| Insulation resistance | Ω | 500VDC / 60sec | >10¹¹ | ASTM D257 |

| Withstand voltage | mA | 4.25kVDC / 60sec | < 0.01 | ASTM D149 |

04Product Features

- feature 01Implements highly consistent rebound elasticity across a wide range of compression levels.

- feature 02Ensures long-term material performance stability under various exposure environment cycles caused by battery charging and discharging.

- feature 03Meets fire resistance standards of UL-HBF or higher.

- feature 04Prevents damage to battery packs caused by deformation due to the expansion and contraction of secondary battery cells during charging and discharging.

- feature 05Provides cushioning functionality while simultaneously blocking heat transfer between battery cells.

- feature 06Serves as a compression pad capable of delaying and preventing flame propagation during thermal runaway-induced ignition.